热力学数据库

组元 (20)

本数据库中共包含以下以下20个组元:

Al-B-C-Co-Cr-Cu-Fe-Mn-Mo-Nb-Ni-O-Pt-Re-Si-Ta-Ti-V-W-Zn-Zr

推荐使用的成分范围

表 1 列出了各个元素推荐使用的成分范围。注意该表给出的范围非常保守,该成分范围都经过大量多元商业合金的实验验证。事实上,很多元素可以应用于更宽的范围,部分二元体系和三元体系在全浓度范围内进行了优化评估,能够适用于0-100%整个浓度范围,详见优化的子体系。

| 组元 | 成分范围 (wt.%) |

|---|---|

|

Co |

50-100 |

|

Al, Ni |

0-50 |

|

Cr |

0-30 |

|

Fe, Mo, Re, Ta, W |

0-20 |

|

Nb, Ti, Zr |

0-10 |

|

B,C,Cu,Mn,O,Pt,Si, V |

0-0.5 |

PanCo2024 的新特性

增加了元素 O 以及优化了所有与 O 相关的 O-X 二元子体系。

相

该数据库共包含 379 个相。表 2 列出了主要相的名称和热力学模型。全部相的信息可以参见PanCo2024:全部相列表,或在Pandat™软件中加载数据库之后从TDB viewer中查看。

优化的子体系

PanCo2024数据库一共优化评估了277个子体系,包括187个二元体系和90个三元体系。下面是具体的体系,体系后面括号中的数字代表优化程度,0为没有优化,10为全成分范围内完全优化评估。

二元体系 (187)

| Al-B(10) | Al-C(10) | Al-Co(10) | Al-Cr(10) | Al-Cu(10) | Al-Fe(10) | Al-Mn(10) |

| Al-Mo(10) | Al-Nb(10) | Al-Ni(10) | Al-O(10) | Al-Pt(10) | Al-Re(10) | Al-Si(10) |

| Al-Ta(10) | Al-Ti(10) | Al-V(10) | Al-W(10) | Al-Zr(10) | B-C(10) | B-Co(10) |

| B-Cr(10) | B-Cu(10) | B-Fe(10) | B-Mn(10) | B-Mo(10) | B-Nb(10) | B-Ni(10) |

| B-O(10) | B-Pt(10) | B-Re(10) | B-Si(10) | B-Ta(10) | B-Ti(10) | B-V(10) |

| B-W(10) | B-Zr(10) | C-Co(10) | C-Cr(10) | C-Cu(10) | C-Fe(10) | C-Mn(10) |

| C-Mo(10) | C-Nb(10) | C-Ni(10) | C-O(10) | C-Pt(10) | C-Re(10) | C-Si(10) |

| C-Ta(10) | C-Ti(10) | C-V(10) | C-W(10) | C-Zr(10) | Co-Cr(10) | Co-Cu(10) |

| Co-Fe(10) | Co-Mn(10) | Co-Mo(10) | Co-Nb(10) | Co-Ni(10) | Co-O(10) | Co-Pt(10) |

| Co-Re(10) | Co-Si(10) | Co-Ta(10) | Co-Ti(10) | Co-V(10) | Co-W(10) | Co-Zr(10) |

| Cr-Cu(10) | Cr-Fe(10) | Cr-Mn(10) | Cr-Mo(10) | Cr-Nb(10) | Cr-Ni(10) | Cr-O(10) |

| Cr-Pt(10) | Cr-Re(10) | Cr-Si(10) | Cr-Ta(10) | Cr-Ti(10) | Cr-V(10) | Cr-W(10) |

| Cr-Zr(10) | Cu-Fe(10) | Cu-Mn(10) | Cu-Mo(10) | Cu-Nb(10) | Cu-Ni(10) | Cu-O(10) |

| Cu-Pt(10) | Cu-Re(10) | Cu-Si(10) | Cu-Ta(10) | Cu-Ti(10) | Cu-V(10) | Cu-W(10) |

| Cu-Zr(10) | Fe-Mn(10) | Fe-Mo(10) | Fe-Nb(10) | Fe-Ni(10) | Fe-O(10) | Fe-Pt(10) |

| Fe-Re(10) | Fe-Si(10) | Fe-Ta(10) | Fe-Ti(10) | Fe-V(10) | Fe-W(10) | Fe-Zr(10) |

| Mn-Mo(10) | Mn-Nb(10) | Mn-Ni(10) | Mn-O(10) | Mn-Pt(10) | Mn-Re(8) | Mn-Si(10) |

| Mn-Ta(10) | Mn-Ti(10) | Mn-V(10) | Mn-W(6) | Mn-Zr(10) | Mo-Nb(10) | Mo-Ni(10) |

| Mo-O(10) | Mo-Pt(10) | Mo-Re(10) | Mo-Si(10) | Mo-Ta(10) | Mo-Ti(10) | Mo-V(10) |

| Mo-W(10) | Mo-Zr(10) | Nb-Ni(10) | Nb-O(10) | Nb-Pt(10) | Nb-Re(10) | Nb-Si(10) |

| Nb-Ta(10) | Nb-Ti(10) | Nb-V(10) | Nb-W(10) | Nb-Zr(10) | Ni-O(10) | Ni-Pt(10) |

| Ni-Re(10) | Ni-Si(10) | Ni-Ta(10) | Ni-Ti(10) | Ni-V(10) | Ni-W(10) | Ni-Zr(10) |

| O-Pt(5) | O-Re(5) | O-Si(10) | O-Ta(10) | O-Ti(10) | O-V(10) | O-W(10) |

| O-Zr(10) | Pt-Re(10) | Pt-Si(10) | Pt-Ta(10) | Pt-Ti(10) | Pt-W(10) | Pt-Zr(10) |

| Re-Si(10) | Re-Ta(10) | Re-Ti(10) | Re-W(10) | Re-Zr(10) | Si-Ta(10) | Si-Ti(10) |

| Si-V(10) | Si-W(10) | Si-Zr(10) | Ta-Ti(10) | Ta-V(10) | Ta-W(10) | Ta-Zr(10) |

| Ti-V(10) | Ti-W(10) | Ti-Zr(10) | V-Zr(10) | W-Zr(10) |

三元体系 (90)

| Al-C-Co(10) | Al-Co-Nb(10) | Al-Co-Ni(10) | Al-Co-W(10) | Al-Fe-Mo(10) | Al-Mn-Si(10) |

| Al-Mo-Ti(10) | Al-Nb-Ti(10) | Al-Ni-Si(10) | Al-Ni-W(10) | Al-Ta-Ti(10) | Co-Cr-Ti(10) |

| Co-Ni-W(10) | Cr-Mn-Ni(10) | Cr-Nb-Ni(10) | Cr-Ni-Si(10) | Cr-Ni-W(10) | Fe-Ni-Ti(10) |

| Mn-Ni-Si(10) | Mn-Nb-Ta(10) | Ni-Si-Ti(10) | Re-Ta-W(10) | C-Co-Cr(8) | C-Co-Fe(8) |

| C-Cr-Fe(8) | C-Fe-Mn(8) | C-Mo-Ti(8) | Al-Co-Cr(8) | Al-Co-Mn(8) | Al-Cr-Ni(8) |

| Al-Cr-Ti(8) | Al-Fe-Ni(8) | Al-Mn-Ni(8) | Al-Mo-Ni(8) | Al-Ni-Ti(8) | Co-Cr-Fe(8) |

| Co-Cr-Mo(8) | Co-Cr-Nb(8) | Co-Cr-Ni(8) | Co-Cr-W(8) | Co-Cu-Fe(8) | Co-Mn-Ni(8) |

| Co-Mo-W(8) | Fe-Nb-Ni(8) | Fe-Ni-Si(8) | Al-Ni-Ta(7) | Co-Ta-Ti(7) | Cr-Fe-Mn(7) |

| Cr-Fe-Ni(7) | Fe-Mn-Nb(7) | Nb-Ni-Ti(7) | Al-C-Fe(6) | Al-C-Ni(6) | C-Co-Mo(6) |

| C-Co-Nb(6) | C-Co-Ta(6) | C-Co-Ti(6) | C-Cr-Mo(6) | Co-Fe-Ta(6) | Co-Fe-W(6) |

| Co-Ni-Ta(6) | Cr-Fe-Mo(6) | Cr-Ta-W(6) | Fe-Mn-Ti(6) | Mo-Ni-Ta(6) | Mo-Ni-Ti(6) |

| Mo-Ta-W(6) | Al-Co-Ta(5) | Al-Co-Ti(5) | Al-Fe-Ta(5) | Al-Nb-Ni(5) | Co-Fe-Mn(5) |

| Co-Fe-Mo(5) | Co-Fe-Ni(5) | Co-Mo-Ni(5) | Co-Mo-Ta(5) | Co-Mo-Ti(5) | Co-Nb-Ti(5) |

| Co-Ni-Si(5) | Co-Ni-Ti(5) | Cr-Mo-Ni(5) | Cr-Mo-Ta(5) | Cr-Ni-Ti(5) | Fe-Mo-Ti(5) |

| Mn-Nb-Si(5) | Mn-Ni-Ta(5) | Mn-Ni-W(5) | Nb-Si-W(5) | Ni-Re-W(5) | Co-Cr-Ta(2) |

数据库的验证

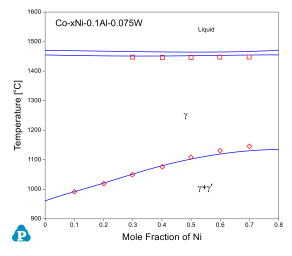

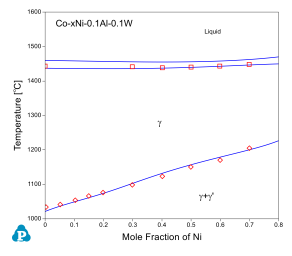

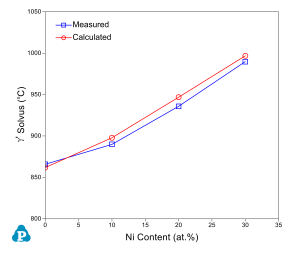

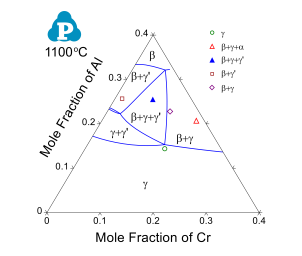

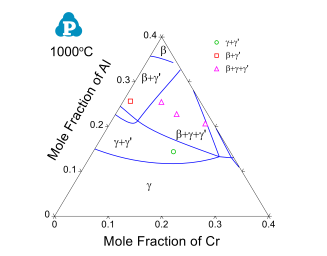

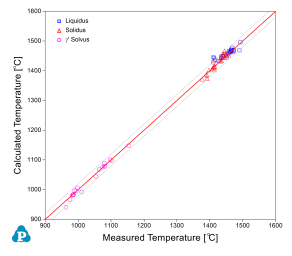

当前版本的钴基合金热力学数据库经过大量发表的实验数据的测试和验证 [2008Ish, 2008Shi, 2010Bau, 2010Pol, 2012Bau, 2015Mak, 2015Mak2]。 图 1 和 图 2 展示了Co-Al-Ni-W四元体系的垂直截面计算相图和实验数据[2008Ish, 2008Shi]的对比。这两个垂直截面中以合金中Ni元素成分与温度为变量,Al和W的成分分别为10 at.% Al和7.5 at.% W(图 1),以及10 at.% Al和10 at.%W(图 2)。从两图中可以看出,计算的相边界与实验值吻合很好。Makineni等人发现了一种新型无钨的γ/γ' Co基高温合金,其成分为Co-10Al-5Mo-2Nb(at.%)[2015Mak, 2015Mak2]。添加Ni形成Co-xNi-10Al-5Mo-2Nb(x取值范围是0-30 at.%),进一步提高固溶线温度。图 3所示为该合金γ'相的固溶线温度的计算值与实验值对比。图 4 和 图 5分别为Co-Ni-Al-Cr四元体系在1000°C和1100°C下,Ni含量为60%的等温截面计算相图。计算结果与实验值(退火合金样品)吻合良好[2006Bur]。图 6所示为计算的液相线、固相线和'相固溶线温度与实验值的对比 [2010Bau, 2010Pol, 2012Bau]。

[2006Bur] J. Bursik, P. Broz, J. Popovic, Microstructure and phase equilibria in Ni-Al-Cr-Co alloys, Intermetallics14 (2006): 1257-1261.

[2008Ish] K. Ishida, Intermetallic Compounds in Co-base alloys - Phase Stability and Application to Superalloys, MRS proceedings, 1128 (2008), DOI: http://dx.doi.org/10.1557/PROC-1128-U06-06.

[2008Shi] K. Shinagawa et al., Phase Equilibria and Microstructure on γ' Phase in Co-Ni-Al-W System, Materials Transactions49(6) (2008): 1474-1479.

[2010Bau] A. Bauer, S. Neumeier, F. Pyczak, M. Göken, Scr. Mater. 63 (2010): 1197-1200.

[2010Pol] T.M. Pollock, J. Dibbern, M. Tsunekane, J. Zhu, A. Suzuki, JOM 62 (2010): 58-63.

[2012Bau] A. Bauer, S. Neumeier, F. Pyczak, M. Gken, Creep properties of different gamma'-strengthened Co-base superalloys, Mater. Sci. Eng. A 550 (2012): 333-341.

[2015Mak] S.K. Makineni, B. Nithin and K. Chattopadhyay, Acta Materialia, 85 (2015): 85-94.

[2015Mak2] S.K. Makineni, B. Nithin and K. Chattopadhyay, Scripta Materialia, 98 (2015): 36-39.